ENGINEERING & PROCESS

EQUIPMENT SUPPLIES

(EPE)

The EPE division represents reputed equipment manufacturers with unmatched service records all over the world. Flowtronix’s EPE division is qualified and registered with operating companies all over GCC. Our services include Design, Engineering, Manufacturing, Fabrication, Construction Management, Installation, Testing and Commissioning of facilities and plants.

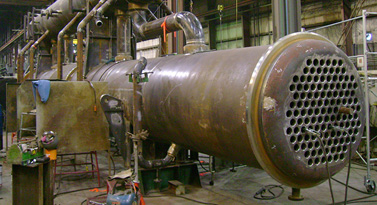

SCHOELLER-BLECKMANN NITEC, member of Christof Group, specializes in manufacturing equipments for the fertilizer

and petrochemical industries. SBN’s products have received worldwide reputation as superior quality process equipment

manufacturer, who specializes in manufacturing of apparatus for Ammonia and Urea Plants.

History of SBN dates back to 1862, when Alexander Schoeller acquired the iron and steelworks in Ternitz.

SCHOELLER-BLECKMANN began fabrication of apparatus for chemical, food & beverages industries in 1935

and was taken over in 1996 by Nooter Corp., St. Louis, Mo. SBN was taken over in April 2008 by the

Christof Group. SBN has gained the position as one of the world’s leading manufacturers of top-quality

high-pressure equipment and is massively supported by its affiliate company – ACE, also a leading

manufacturer of Process Apparatus.

SPECTRUM OF SERVICES

- High pressure strippers

- High pressure scrubbers

- Pool condensers

- Pool reactors

- High pressure reactors

- High-pressure Carbamate condensers

- Internals

- High pressure piping parts

SPECTRUM OF SERVICES

- Converter shells

- Converter internals

- Synthesis gas heat exchangers

- Waste Heat Boilers

- Transfer lines

SPECTRUM OF SERVICES

- Hydrogenation processes

- Refineries

- Vessels for special applications Vessels for CO2 absorption | Vessels for other high-pressure processes | Separators for LDPE plants | Reactors for wet air oxidation | Reactors for caprolactam plants | Absorbers for gas drying | Reactors for melamine plants

Fatty alcohol

Hydrocrackers | Hydrotreaters

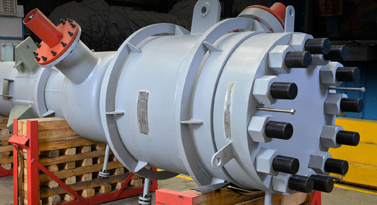

Founded in 1968 with headquarters and operational center in Madignano, (CR) Italy, 40 km from Milano.

VS is a well-established company operating in the field of design, building of equipment & plants for the chemical,

petroleum and refrigerating industries.

The workshop covers about 18.000 sqmt. including machinery, welding and fitting floors. The facilities are also equipped with:

Titanium dedicated clean room an immersion pool for pneumatic testing, RX bunker, blasting & painting area. This enables VS to

cover all phases of design, production and testing.

BLAGDON PUMP was originally founded in the early 1950’s as a specialist pump manufacturer. BLAGDON commenced production of Air Operated Double Diaphgram (AODD) Pumps in 1979. BLAGDON has been a part of IDEX Corporation since 1997.

BLAGDON PUMP complies with all British Standards BS EN ISO 9001:2000 Quality Management Systems and BS EN ISO 14001:2004 Environment Management Systems.

The Blagdon Pumps metal range is available from ¼” to 3″ connection sizes, with flows from 4 lpm to 850 lpm and a maximum pressure of up to 8bar. Blagdon pump casings are available in stainless steel, aluminium and cast iron with various component and material options.

A full range of elastomer options are available in each pump and size. Different materials that are suitable are: buna, neoprene, EPDM, viton, polyurethane, santoprene and PTFE.

The Blagdon pumps non-metallic plastic range is available from ¼” to 2″ connection sizes, with flows from 4 lpm to 500 lpm and a maximum pressure of up to 8bar. Blagdon pump wetted casings come in polypropylene and PVDF.

A full range of elastomer options are available in each pump and size. Different materials that are suitable are: Buna, neoprene, EPDM, Viton, Polyurethane, Santoprene and PTFE.

The Blagdon PTFE pump range is available in ½” & 1” connection sizes. The Blagdon pump PTFE pump range is constructed solely of PTFE wetted casings and PTFE Elastomers.

There are two option of PTFE from Blagdon to choose from which are standard PTFE or Conductive PTFE. The air chambers which are the non-wetted components are available in Conductive PTFE, Polyethylene (HDPE) or 316 Stainless Steel.

The Blagdon high pressure Pump range is available with 1″ to 2″ connection sizes, with flows up to 341 lpm and with a maximum 16 bar discharge pressure with an 8 bar airline pressure. Blagdon pumps wetted casings are available in 316 stainless steel and aluminium with a full range of elastomer options. Different materials options that are suitable are: Buna, neoprene, EPDM, Viton, Polyurethane, Santoprene and PTFE.

The Blagdon hygienic pump range is available from ½” to 2″ connection sizes, with flows from 10 lpm to 476 lpm and a maximum pressure of up to 8 bar. The Blagdon pump wetted casings that are available are in electro-polished stainless steel with various component material options and EPDM/PTFE food grade elastomers.

There are different connection options (DIN/RJT & ferrule) and is certified CIP cleanable. This range has EHEDG certification.

Blagdon Pump as well as offering their standard of the shelve pump range can also offer bespoke custom pumps to meet your specific requirements or application. In the past Blagdon pumps have custom built pump units for the below sizes and materials.